Lub sawb hlau yog raug rau qhov txias txias-bending deformation los tsim Z-puab, U-puab lossis lwm yam zoo li hauv seem, uas tuaj yeem txuas rau ib leeg los ntawm kev xauv rau lub hauv paus daim hlau.

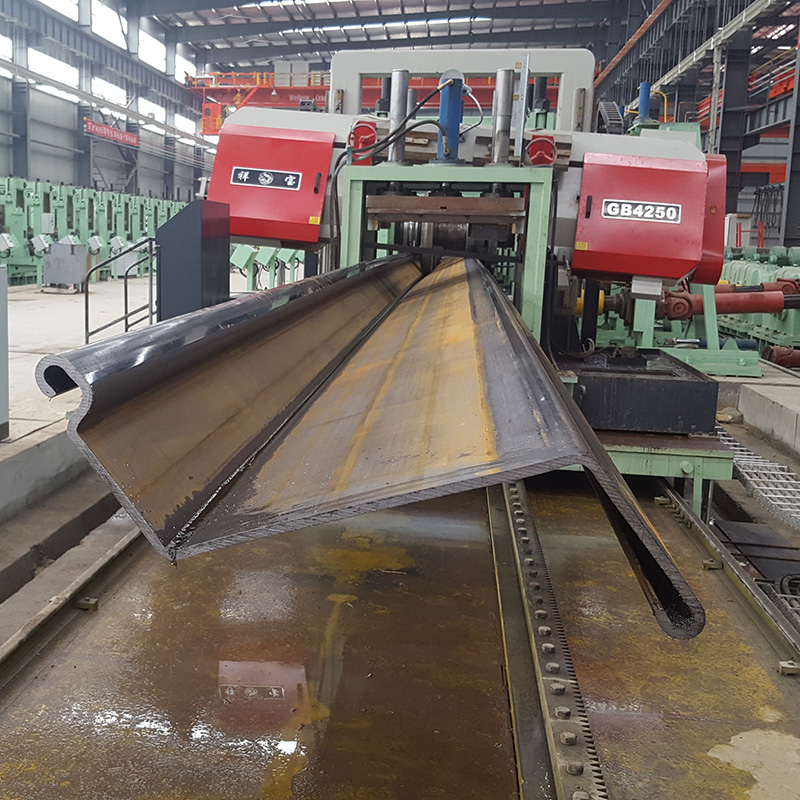

Cov nplooj ntawv steel uas tsim los ntawm dov txias-tsim yog cov khoom tseem ceeb ntawm cov hlau ua kom txias hauv civil engineering.Cov kab ntawv steel yog tsav (nias) rau hauv lub hauv paus nrog ib pawg tsav tsheb los txuas rau lawv los tsim cov ntawv steel pawg phab ntsa rau khaws cov av thiab dej tuav.Feem ntau siv hla ntu yog: U-puab, Z-puab thiab ncaj web hom.Cov ntaub ntawv hlau yog tsim rau kev txhawb nqa cov hauv paus mos thiab lub hauv paus tob tob nrog cov dej hauv av siab.Kev tsim kho yog qhov yooj yim, thiab nws qhov zoo yog kev ua haujlwm zoo hauv dej-nres thiab tuaj yeem rov siv dua.Kev xa khoom ntawm cov ntawv steel piles Lub sijhawm xa khoom ntawm cov ntawv txias txias yog 6m, 9m, 12m, 15m, thiab tuaj yeem ua tiav raws li cov neeg siv khoom xav tau, nrog qhov ntev tshaj plaws ntawm 24m.(Yog tias tus neeg siv muaj qhov tshwj xeeb ntev yuav tsum tau, nws tuaj yeem thov thaum xaj) Cov ntawv txias-tsim steel pawg yog xa los ntawm qhov hnyav tiag tiag, lossis los ntawm qhov ntsuas qhov ntsuas.Daim ntawv thov ntawm steel ntawv pawg Txias-tsim steel ntawv pawg cov khoom lag luam muaj cov yam ntxwv ntawm kev tsim kho yooj yim, kev vam meej sai, tsis xav tau cov khoom siv loj loj, thiab cov qauv tsim zoo nkauj hauv kev siv engineering, thiab cov duab ntoo khaub lig-tsim steel ntawv. pawg tuaj yeem hloov pauv raws li cov xwm txheej tshwj xeeb ntawm qhov project thiab ntev, ua rau cov qauv tsim kev lag luam thiab tsim nyog.Tsis tas li ntawd, los ntawm kev tsim kho kom zoo ntawm ntu ntawm cov khoom siv txias-tsim steel ntawv pawg, cov khoom lag luam zoo tau raug kho kom zoo dua qub, qhov hnyav ib 'meter' ntawm pawg phab ntsa dav tau raug txo, thiab qhov project nqi raug txo.

Cov cuab yeej muaj qhov zoo hauv qab no:

● Txhim kho kev ua haujlwm thiab kev ua haujlwm ntau lawm

● High degree ntawm automation, txo cov neeg ua haujlwm tawm tswv yim

● Txhim kho qhov chaw ua haujlwm thiab kev nyab xeeb

● Txhim kho qhov ruaj khov ntawm cov khoom zoo, ruaj khov thiab txhim khu kev qha molding, thiab tuaj yeem ua tau raws li cov khoom siv nrog cov tuab thiab lub zog sib txawv

● Txhim kho cov khoom tawm los

● Txo tus nqi ntawm cov khoom siv

●Siv lub German COPRA dhau kev tsim software, los ntawm kev txheeb xyuas qhov kev sib txawv ntawm cov txheej txheem txias-bending profile, qhov tsim nyog tshaj plaws txias-bending forming txheej txheem thiab deformation dhau tuaj yeem txiav txim siab ua ntej yob yog tsim, thiab cov txheej txheem simulation tshuab muaj peev xwm. siv los simulate Nyob rau hauv tus txheej txheem ntawm txias yob txoj kev, lub yob tsim yog optimized, thiab cov kev nyuaj siab-strain simulation yog siv los xyuas seb puas muaj ib tug txaus ntshai cheeb tsam uas yuav ua rau tsis xws luag nyob rau hauv lub tsim.

● Txhawm rau txuag lub sijhawm rau kev hloov cov yob thaum hloov cov kev qhia tshwj xeeb, kev hloov pauv ceev ceev thiab tsav cov ncej nrawm nrawm, thiab cov cuab yeej hloov pauv tau npaj.

Post lub sij hawm: Feb-21-2023